A Clean-Out-Of-Place (COP) Parts Washer is a portable stainless-steel wash tank that cleans hard-to-wash processing items and machine parts. Its stainless-steel wash basin is full of hot water and often chemicals and may contain baskets to hold small parts. Inside this basin are four high-velocity jets that provide continuous rolling action to loosen and remove stuck-on grime.

This washer’s wheels allow operators to roll the wash basin around the facility with ease.

What Does Clean Out Of Place Mean?

Clean out of place (COP) involves disassembling equipment to clean its individual parts, instead of cleaning the equipment as-is. Operators use this method for equipment that’s difficult to effectively clean in its regular form. Operators remove the parts from the machine and clean them in another location, hence the term “clean out of place”.

This is different from the Clean In Place (CIP) method, which is a way to clean a machine without dismantling it. In this method, operators temporarily or permanently attach an automated cleaning system to their soiled equipment.

Why Would You Clean Out Of Place?

Processing equipment, especially in the food industry, often has very specific parts that are difficult to fully sanitize while still attached. This could be due to their odd shape (like hoses or valves), or their location on the machine.

Detaching these parts and cleaning them separately allows the operator to make sure their equipment is completely clean, adhering to food safety standards and maintaining the safety and quality of their products.

How Does A COP Parts Washer Work?

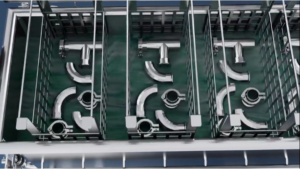

Baskets of machine parts are submerged into the COP.

The Douglas COP parts washer cleans items and parts by immersion. Once the items are fully submerged, they are washed and sanitized by a combination of hot water, chemicals, and powerful currents.

The wash tank has radius corners and a seamless interior free from protrusions to encourage water and chemical circulation.

A high-efficiency motor pumps hot water into the wash basin through an in-spout manifold fitted with a spray guard to direct the water down the interior walls for a quick controlled fill. This way, the operator can load the process items prewash without a fear of overspray.

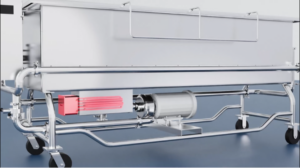

The heating element is highlighted in red.

Heat is crucial in the battle against microbes. The Douglas COPs use either live steam injection heaters or immersion heaters so the water is at bacteria-killing temperatures.

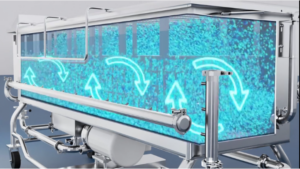

The strategic position of sprayer heads within the wash tank creates continuous, turbulent action to clean the items. Cycling between four jets, the COP washer ensures rigorous removal of soil from parts.

An optional lid will help the washer heat up faster and retain heat longer. Soft close lift pistons help the operator easily open and close the lid and protect from splash.

Water circulates within the COP to remove grime.

The COP’s wheels are outfitted with lockable industrial casters, so it effortlessly glides around any workspace and locks in place for ease of transport to the wash site.

When finished, the supply manifold valves drain the tank. Once empty, an easy-access filter basket allows for cleaning and maintenance.

Clean-out-of-place systems are used across industries and applications to wash and sanitize items and parts. If you’d like to learn more about how a COP could fit into your operation, you can reach out to a Douglas Machines Corp. engineer.