Commercial and Industrial

Washing & Sanitizing Systems

This website may use cookies and/or other technologies to improve user experience and track website usage. By using this site, you acknowledge that you have read, understand and agree to our privacy policy. Learn More

40 YEARS LEADING THE INDUSTRY

Since 1979, Douglas Machines Corp. has been a specialist in the design and manufacture of automated washing and sanitizing equipment.

We have developed the most comprehensive product line in the industry and enjoy an outstanding reputation for performance and reliability.

Each Douglas washer is backed by one of the strongest warranty and service programs in the industry.

AUTOMATE YOUR CLEANING PROCESS

As a leading manufacturer of commercial and industrial washers, we offer a variety of commercial and industrial washers.

No matter your washing need, we have an industrial washer suitable for you.

Training and commissioning are provided with each unit to ensure proper maintenance and years of dependable, trouble-free operation.

SYSTEMS

Our customers trust us to deliver tailored, industry-specific solutions that maximize productivity and increase equipment shelf life. We have over 80 high-performance commercial sanitizing systems, plus the ability to custom-design a machine.

SERVICE

Maintenance is crucial to keeping your machine running well long-term. That’s why certified Douglas Machines Corp. technicians are on hand to keep your system at peak performance, along with our vast global network of service providers.

PARTS

We store an extensive inventory of spare machine parts in-house to ensure that you never have to look far for the right machine part. If we have your part in stock, we’ll ship it before 2:30 PM EST the same day. If not, we’ll acquire the part quickly to get you up and running as soon as possible.

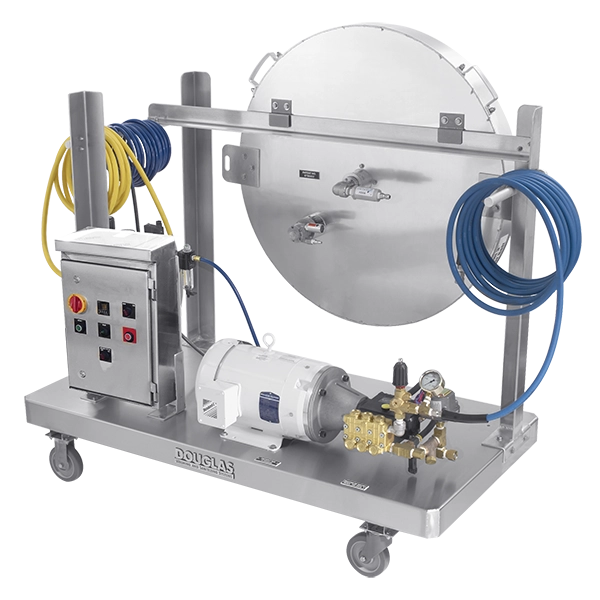

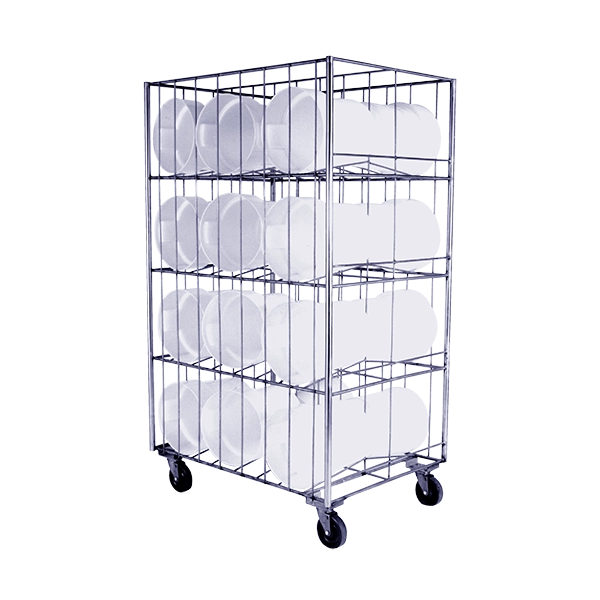

Stainless Steel Commercial Washers

The ideal commercial washer system for your company depends on the type and level of grime being removed, your processing time, your utilities, space limitations, and your budget. To get a quick overview of our standard models, scroll over the images below or download the comprehensive Buyer’s Guide. If none of the models below fit your needs, speak to an engineer and design a custom system tailored to your needs.

Pots, Pans and Container Washers

Roll-in Rack Washers

Scale Parts Washers

Vat, Bin and Tote Washers

Conveyorized Tunnel Washer

Smoke Truck Washer

Barrel, Drum, and Garbage Can Washers

Belt Washer

COP Parts Washer

Bucket Washers

Wash Rack

TRUSTED PARTNERS

PARTNERED ASSOCIATIONS

Phone

info@dougmac.com

Corporate Office

4500 110th Ave N

Clearwater, FL 33762

Business Hours

Monday -Friday 8:00am - 4:30pm

Connect With Us

Reach Out to Us

Have a question? Our experienced sales and engineering staff is ready to assist you in identifying the very best Douglas Washer or Replacement Part to match your specific needs. Call 888-348-3947 for parts and service or email us today. We are here to help you!